Calce pelable de alta precisión Laminum® HP

Añadir a mis favoritos

Añadir al comparador

Características

- Especificaciones

- de alta precisión

Descripción

Laminum® HP

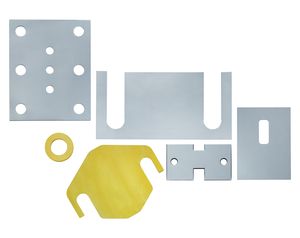

High-precision laminated shims

When mounting sub-assemblies, tolerance compensation can be optimized to 10 micrometres with the Laminum® HP. The special feature of these shims is the combination of several peelable shims with a thickness of 0.05 mm with one or more final high-precision films of lesser thicknesses.

These high-precision films even serve as the last step in manual fine tuning when tolerances in the 25 µ and/or 10 µ range have to be compensated. The new combined Laminum® HP solution is a time and cost-optimized alternative to a spacer element laminated over its entire surface with 25µ films, as the expense and effort required for production are lower than with fully coated 0.025 millimetre laminates.

At the same time, Laminum® HP1 helps users to reach their goal more quickly, as peeling the thicker 0.05 mm films by hand is much faster.

Practical use of the high-precision shims in the mounting of sub-assemblies is also facilitated by the fact that the precision films have a small, slightly raised finger lift which can be easily recognised, thus making peeling much simpler.

VÍDEO

Catálogos

No hay ningún catálogo disponible para este producto.

Ver todos los catálogos de Georg Martin GmbHBúsquedas asociadas

- Capuchón de extremo de plástico

- Capuchón de extremo redondo

- Capuchón de extremo de protección

- Palanca de mando

- Calce

- Tope amortizante

- Capuchón de extremo de ABS

- Capuchón de extremo con arandela

- Calce macizo

- Calce pelable

- Calce de acero inoxidable

- Tope amortizante de acero

- Calce de ajuste

- Calce de plástico

- Calce de metales

- Calce para alineación

* Los precios no incluyen impuestos, gastos de entrega ni derechos de exportación. Tampoco incluyen gastos de instalación o de puesta en marcha. Los precios se dan a título indicativo y pueden cambiar en función del país, del coste de las materias primas y de los tipos de cambio.