- Hidráulica - Neumática

- Tubería, Racor

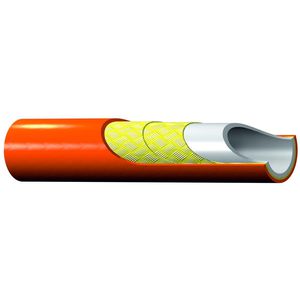

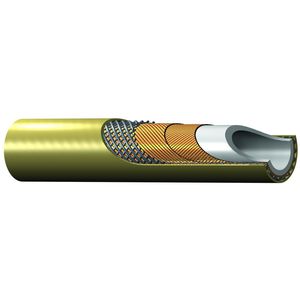

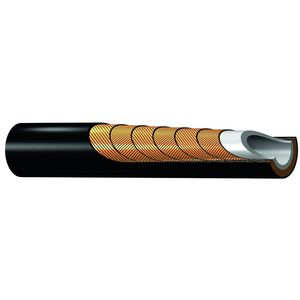

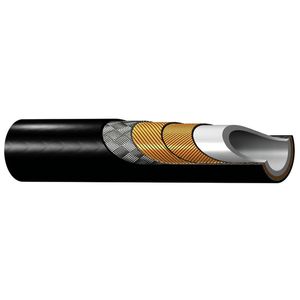

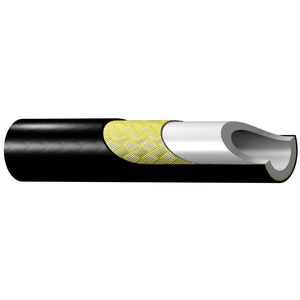

- Manguera de hidrógeno

- Parker Polyflex Division - Europe

Manguera de hidrógeno 2440P-04V32para carburantede polímerode alta presión

Añadir a mis favoritos

Añadir al comparador

Características

- Uso previsto

- para carburante, de hidrógeno

- Material

- de polímero

- Uso previsto

- de alta presión, de transferencia, de baja temperatura

- Otras características

- robusta, de espiralado metálico

- Diámetro interno

6,4 mm, 13 mm

(0,252 in, 0,512 in)- Diámetro externo

13 mm, 22,7 mm

(0,512 in, 0,894 in)- Presión

15.000 psi

- Temperatura

Mín.: -40 °C

(-40 °F)Máx.: 85 °C

(185 °F)

Descripción

Parker Hydrogen Hose Assemblies are engineered to provide a leak-proof solution for high-pressure hydrogen dispensing and hydrogen transfer, supporting pressures up to 103.5 MPa. Each hose assembly is factory-assembled and pressure-tested to ensure reliable operation and long lifecycle in critical hydrogen applications.

Parker hydrogen hose assemblies meet or exceed international hydrogen standards, such as ISO 19880-5 and ANSI/CSA HGV 4.2 - pressure class H70. Moreover, the -4 size hose is fully certified by a third party to ANSI/CSA HGV 4.2.

Features/Benefits

- Leak-tight assembly due to a perfect fit of hose and fittings, even at temperatures as low as -40 °C: highest safety for extremely critical applications

- Durable construction: extended service life and reduced frequency of replacement

- Proven performance: recognized as a leading product through extensive field testing

- Ease of use: a tight bend radius allows for easy installation in tight spaces

- High kink resistance: minimized risk of hose damage by end user

- Fast refueling at -40°C: low refilling time for end user

- Hose size -4: HGV 4.2 certified, first hose certified to HGV 4.2 to meet this market requirement

- Meets or exceeds ISO 19880-5: the hose meets the highest market requirements

- Low permeation rates: improved safety (gas concentrations) and minimized hydrogen loss

- Enhanced safety: exceeds H70 pressure requirements with a 103.5 MPa working pressure capacity in case of pressure spikes

Catálogos

2440P-04V32 Hydrogen Hose

2 Páginas

Otros productos de Parker Polyflex Division - Europe

Polyflex Division Europe

Búsquedas asociadas

- Racor Parker

- Tubería Parker

- Racor hidráulico Parker

- Racor neumático

- Racor de metal

- Manguera de plástico Parker

- Racor de acero inoxidable Parker

- Racor de ángulo

- Manguera estructura Parker

- Tubería flexible flexible

- Manguera a prueba de abrasión Parker

- Manguera para agua Parker

- Racor macho

- Racor hembra

- Manguera trenzado de metal Parker

- Manguera reforzada Parker

- Tubería lisa

- Racor codo de 90º

- Racor de clapeta

- Manguera lisa

* Los precios no incluyen impuestos, gastos de entrega ni derechos de exportación. Tampoco incluyen gastos de instalación o de puesta en marcha. Los precios se dan a título indicativo y pueden cambiar en función del país, del coste de las materias primas y de los tipos de cambio.